You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

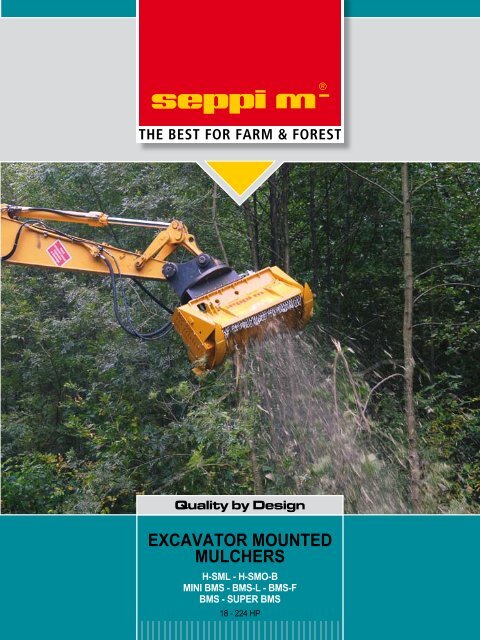

Quality by Design1<strong>EXCAVATOR</strong> <strong>MOUNTED</strong><strong>MULCHERS</strong>H-SML - H-SMO-BMINI BMS - BMS-L - BMS-FBMS - SUPER BMS18 - 224 HP

Discover theAdvantages ofINNOVATION> nearly 70 years experience, over 35 in mulching> continuous research for new solutions and technologies> optimal materialQUALITY> every machine is tested before leaving the factory> use of the best components only> low wearRELIABILITY> excellent working machines> easy maintenance> fast and efficient after sales service2

<strong>EXCAVATOR</strong> <strong>MOUNTED</strong> <strong>MULCHERS</strong>The excavator mounted mulchers come with hydraulic drive andhave been made specifically for being mounted on excavatorarms.With the combination excavator + mulcher it is possible to reachremote and difficult to access areas, uneven grounds, marshlandor steep slopes. The SEPPI mulchers for excavators are greattools for greenspace maintenance as well as for maintaining powerlines, roadsides and riverbanks. When preparing constructionsites, they help eliminating stumps, trunks and all other vegetation.Excavator mounted mulchers by SEPPI M.:› for excavators from 3 to 35 tons› for mulching grass, brush and wood up to 5, 7, 20 and40 cm in diameterexcavator mounted mulchers for:1 – greenspace maintenanceH-SMLH-SMO-B2 – light forestry mulchersMINI BMSBMS-LBMS-F3 – heavy duty forestry mulchersBMSSUPER BMSHow to work with an excavator mountedmulcher by SEPPI M.?Excavator mounted mulchers are great machines withwhich to maintain difficult to access greenspace. Theyare offered in a wide range from small to very large.The range of excavator mounted mulchers by SEPPI M.weight kg [lb]300025002000150010009008007006005004003002001006613551244093307220519841764154313231103882661441221MINI BMSH-SMLBMS-F BMS-L MINI-BMSH-SMO-BBMSSUPER BMSnecessary oil flowl/min [US-gal/min]0 50 [13] 100 [26] 150 [40] 200 [53] 250 [66] 300 [79] 350 [92] 400 [106]3

H-SML :: H-SMO-BExcavator + mulcher.A winning couple for greenspace maintenance!3-13 t / 25-54 HPfeatures H-SML H-SMO-Bmulches grass and prunings 5 cm [2”] Ø 7 cm [2.8”] Øfor excavatorsfrom 3 to 5 tons from 5 to 13 tons[6,615-11,023 lb] [11,023-28,660 lb]transmission with hyd. motor* S Sdisposition for attachmentto excavatorSSindirect transmission with 3 belts 4 beltsadjustable rear hood X Sfront protection metal flaps chainsrear protection rubber flap rubber flapadjustable support roller S Sstandard rotor SML flails for shackles SMO flailsS: standard - O: option - X: not available* your SEPPI dealer can help you choose the right motorThe models H-SML and H-SMO-B are strong andversatile mulchers for maintaining wasteland andareas difficult to access. These mulchers can bemounted on small and medium tracked excavatorsor excavators with tyres. A suitable hydraulicsystem is necessary for operation.The mulcher H-SML comes with a light chassis,and a support roller. It is ideal for mini-excavatorsfor maintaining small greenspaces,riverbanks and canals.well protected motorbehind the interfaceplatemechanical floatationbracket to follow thecontours of the ground(optional), may also befitted with rotator (optional)strong belt protectionand low profilemodel: H-SMLmetal flaps on H-SMLprotect even while workingin vertical positionrotor with SMLhammers on shackles(standard on H-SML)4

H-SML :: H-SMO-B3-13 t / 25-54 HPThe H-SMO-B is designed for excavatorattachment. It works with hydraulic transmission.The rear hood allows the adjustment of the degreeof mulching. With the support roller it is possibleto adapt to the contours of the ground andto adjust the height of cut.The H-SMO-B mulches grass and woodup to 7 cm [2.8“] in diameter.options H-SML H-SMO-B OPTrotor with SMO hammersand counterknives(standard on H-SMO-B)model: H-SMO-Brotor with 2 Y flails on shackles O X 031rotor with SMW hammer O X 039valve for inverting the direction of rotation X O 258gear motor S X **variable displacement piston motor O O **interface plate O O 218interface plate with 190° hyd. rotation O O 372floating attachment O O 099additional rubber front protection O O 006S: standard - O: option - X: not available** your SEPPI dealer can help you choose the right motorworkingwidthcm [“]overallwidthcm [“]depthcm [“]heightcm [“]weight*kg [lb]SMLhammers#SMW/SMOhammers#rollerØ mm [“]oil flowl/min[US-gal/min]max.pressurebar [PSI]kWmin-maxHPmin-maxH-SMLH-SMO-B60 [25] 72 [28] 100 [39] 61 [24] 150 [330] 9 6 133 [5]18-25 25-3585 [33] 97 [38] 100 [39] 61 [24] 181 [400] 15 9 133 [5] 20-80 250 18-25 25-35105 [41] 117 [46] 100 [39] 61 [24] 207 [460] 21 9 133 [5] [5-21] [3625] 18-25 25-35125 [49] 137 [54] 100 [39] 61 [24] 235 [520] 24 12 133 [5] 18-25 25-35125 [49] 140 [55] 120 [47] 60 [24] 383 [844] X 12 133 [5]25-40 35-54150 [59] 165 [65] 120 [47] 60 [24] 437 [963] X 15 133 [5] 46–135 250 25-40 35-54175 [69] 190 [75] 120 [47] 60 [24] 483 [1064] X 18 133 [5] [12-36] [3625] 25-40 35-54200 [79] 215 [85] 120 [47] 60 [24] 535 [1179] X 21 133 [5] 25-40 35-54* The weight of the machine refers to the standard, without options, and may vary.5

MINI BMS :: BMS-L :: BMS-FGreat power, little weight:Easy to handle forestry mulching!features MINI BMS BMS-L BMS-Fmulches vegetation up to10 cm [4”] Ø7 (12**) cm[2.8 (4.7**)”] Ø20 cm [8”] Øfor excavatorsfrom 5 to 10 tons from 7 to 15 tons from 13 to 25 tons[11,023-22,046 lb] [15,430-33,069 lb] [28,660-55,116 lb]transmission with hyd. piston motor* O O Odisposition for attachmentto excavatorS S Sindirect transmission with 5 belts 5 belts 5 beltshydraulic hood S S Oskids S adjustable in height adjustable in heightstandard rotorMINI BMSMINIFORSTSMO flailsswinging hammersfixed knivesS: standard - O: option - X: not available* your SEPPI dealer can help you choose the right motor** BMS-L with forestry rotor, OPT 240, 193 or 228. Weight increases by 200 kg [440 lb].5-25 t / 40-80 HPThe mulchers of this series have beendeveloped for medium size excavators.Mounted on the arm of an excavatormulcher, these mulchers will show greatresults in greenspace maintenance onriverbanks, in the forest and inother areas difficult to reach.The BMS-F was designed for specialvehicles, for example on railways. Whenattached to the arm of a railway vehicle,the BMS-F is ideal for maintaining thevegetation alongside railways.The rotor is particularly strong to bearfrequent vertical mulching.The BMS-F mulches woodup to 20 cm [8”] in diameter.special metal chassis forvery strong resistance towear with limited weightmodel: BMS-Fhydraulic piston motorwith relief valve and anticavitationvalvelow profile for morefacility at workfixed knifes rotor withstrong bearings for highperformance even invertical positions6

MINI BMS :: BMS-L :: BMS-F5-25 t / 40-80 HPMINI BMS is the lightest forestrymulcher of the SEPPI range ofexcavator mounted mulchers.Its light weight makes it ideal forattachment to long excavatorarms. This way the mulcher willreach even far off spaces.model: MINI BMSoptionsMINIBMSBMS-L BMS-F OPTmodel: BMS-LWith its double adjustable hood, the model BMS-Lcan work in two directions. Many specific situationsdetermined by the type of vegetation, the soil and theenvironment will thus be easy to handle!With its standard rotor, the BMS-L mulches brush up to7 cm [2.8”] in diameter, with the optional forestry mulcherit will mulch material up to 12 cm [4.7”].swinging hammer forestry rotor S O X 240swinging hammer forestry rotorwith tungsten tipsX O X 193fixed knife rotor with 2 tunsten tips O O S 228valve for inverting the direction of rotation O O X 258variable displacement piston motor O O X **bent axis piston motor O X O **attachment interface O O O 218attachment interface with 190° hyd. rotation O O O 372attachment interface spider excavator X O X 130hydraulic rear hood S S O 317hydraulic front and rear hood X O X 339S: standard - O: option - X: not available** your SEPPI dealer can help you choose the right motorworkingwidthcm [“]overallwidthcm [“]depthcm [“]heightcm [“]weight*kg [lb]SMOhammers#swinginghammers#fixedknives(214) #oil flowl/min[US-gal/min]max.pressurebar [PSI]kWmin-maxHPmin-maxMINIBMSBMS-LBMS-F85 [33] 100 [39] 103 [41] 72 [28] 390 [860] X 13 18105 [41] 120 [47] 103 [41] 72 [28] 430 [948] X 17 21125 [49] 140 [55] 103 [41] 72 [28] 490 [1080] X 20 27100 [39] 131 [51] 80 [31] 73 [29] 450 [992] 9 15 21125 [49] 156 [61] 90 [35] 73 [29] 526 [1159] 12 20 27150 [59] 181 [71] 90 [35] 73 [29] 580 [1279] 15 24 30100 [39] 128 [50] 105 [41] 72 [28] 565 [1245] X X 21125 [49] 153 [60] 105 [41] 72 [28] 640 [1410] X X 27150 [59] 178 [70] 105 [41] 72 [28] 715 [1580] X X 3050-120[13-32]46–135[12-36]75-140[20-37]350[5075]250[3625]350[5075]30-50 40-6725-40 35-5440-60 54-80* The weight of the machine refers to the standard, without options, and may vary.7

BMS :: SUPER BMSGet the most out of your excavator.With these superior SEPPI mulchers!13-35 t / 70-224 HPfeatures BMS SUPER BMSmulches wood up to 25 cm [10”] Ø 40 [16”] cm Øfor excavatorsfrom 13 to 25 tonnes from 20 to 35 tonnes[28,660-55,116 lb] [44,092-77,162 lb]transmission with hyd. piston motor* S Sdisposition for attachment to excavator S Sindirect transmission with 5 belts 10 beltshydraulic hood S Sskids adjustable Sstandard rotorMIDIFORST MAXIFORSTswinging hammersfixed knivesS: standard - O: option - X: not available* your SEPPI dealer can help you choose the right motorThese mulchers are highly powerful and shall beapplied to high performance excavators.The BMS and SUPER BMSare ideal for real toughjobs in the forest, along power lines and onconstruction sites. Especially in the forest these aregreat tools for clearing slash after the wood harvest.Even big stumps and wood up to 25 cm [10”] and40 [16”] cm in diameter are easy to eliminate!universal attachmentinterfacemodel: BMSfixed knife rotor -new generation(optional)very strong casing toresist strong loadprotection chains withmetal plates8

BMS :: SUPER BMS13-35 t / 70-224 HPoptions BMS SUPERBMSOPTswinging hammer rotor with tungsten tips O X 193fixed knife rotor with 2+1 tungsten tips O S 214fixed knife rotor with 2 tungsten tips O O 228bent axis piston motor O O **interface plate O O 372interface plate with 190° hyd. rotation O X 218additional front rubber protection O X 006S: standard - O: option - X: not available** your SEPPI dealer can help you choose the right motorBMSSUPERBMSworkingwidthcm [“]overallwidthcm [“]depthcm [“]heightcm [“]weight*kg [lb]swinginghammers#fixedknives(214) #fixedknives(228) #oil flowl/min[US-gal/min]max.pressurebar [PSI]kWmin-maxHPmin-max100 [39] 131 [52] 105 [41] 85 [33] 920 [2028] 15 16 2051-109 70-150125 [49] 156 [62] 105 [41] 85 [33] 1040 [2292] 20 20 28 100–210 350 51-109 70-150150 [59] 181 [71] 105 [41] 85 [33] 1120 [2468] 24 24 32 51-109 70-150150 [59] 192 [75] 120 [48] 105 [41] 2565 [5656] X 27 3482-165 112-224175 [69] 217 [85] 120 [48] 105 [41] 2825 [6230] X 30 36 200–300 350 82-165 112-224200 [79] 242 [95] 120 [48] 105 [41] 3085 [6803] X 36 42 82-165 112-224* The weight of the machine refers to the standard, without options, and may vary.9

INSTALLATIONThe installation of hydraulic mulchers on an excavator requires some technicalskills and knowledge. This page gives most information needed for the set-up andinstallation of your machine. Nevertheless, we recommend to refer to the user manualfor a detailed description and safety procedures.Attachment interfaceMulchers for excavators can be supplied with a universal interface thatcan accept different attachment plates, depending on the excavatorused. For details or drawings of the universal interface please ask yourSEPPI dealer.WeightThe excavator must be able to carry the weight of the mulcher as indicatedon the ID plate. For many excavators a good approximation is:excavator weight ≥ 15 x mulcher weightPressureTo avoid overheating the circuits the system pressure should neverexceed the indicated maximum pressure. However, all hydraulic motorsdelivered by SEPPI are equipped with top mounted pressure relievevalves set to the right pressure.Case drain pressureAll motors delivered by SEPPI are high performance piston motorswhich need a case drain connection to the tank. The case drainpressure must never exceed the values specified in the table below!modelH-SML, H-SMO-B, BMS-L, MINI BMSMINI BMS, BMS-F, BMS, SUPER BMSdrainage pressuremax. 1.5 bar[21 PSI]max. 5 bar[70 PSI]FlowThe efficiency of the mulcher depends mostly on the speed of the rotor.The speed depends on the flow available from the prime mover and onthe size of the hydraulic motors installed.Upon demand, your SEPPI dealer can help you to define which of theavailable motors will best fit the hydraulic circuit on your prime mover orcompact loader.Hydraulic hoses and connectionsTo install the machine on the prime mover or compact loader, thehydraulic pipes and hoses have to be made on site. For the diameter ofthe hoses take the following table as a reference:pipes andhoses25-50 l/min[7-13US gal/min]recommended diameter100-200 l/min[26-53US gal/min]50-100 l/min[13-26US gal/min]200-400 l/min[53-106US gal/min]400-800 l/min[106-211US gal/min]pressure (P) ¾ ” 1 ” 1 ½ ” 2 ½ ” 2 x 2 ½ ”return (T) ¾ “ 1 ” 1 ½ ” 2 ½ “ 2 x 2 ½ “drainage (D) ½ ” ¾ ” 1 “ 1 “ 1 “Hydraulic hood controlOn forestry mulchers the hood can be opened or closed hydraulically.This requires an additional directional valve. On request this valve canbe delivered by SEPPI.CavitationCavitation happens when the motor runs “dry”, e.g. the hydraulic flowis interrupted but the mulcher continues to rotate. To prevent damagesto the motor due to cavitation all motors are equipped with an “anticavitation”valve mounted on top.Open or closed loopAll hydraulic SEPPI mulchers can be installed on either open or closedloop systems. Closed loop circuits sometimes need extra flushingvalves for cooling. In that case please contact your SEPPI dealer or theSEPPI technical department.SafetySEPPI M. requests to have ROPS/ FOPS standard protected cabinsand to follow all the safety instructions listed in the user manual.Direction of the rotorThe direction is defined on each model.Some mulchers can optionally be fitted with an additional valve whichallows the motor to run in both directions. This will reverse the rotationof the rotor, so swinging hammer rotors will cut in either direction withsuitable extra guarding.10

ROTORS a n d HAMMERSSMW and SMO hammer rotorSWINGING HAMMER rotorSML hammeron shacklestandard onH-SMLY flailon shackleoptional onH-SMLSMW hammeroptional onH-SMLSMO hammerstandard onH-SMO-Bdifferent hammer sizes, according to modelstandard on MINI BMS and BMSoptional on BMS-LFIXED KNIFE rotorFIXED KNIFE rotorover 10 yearsgreat experience!newgenerationhammer with 2+1 tungsten tipsdifferent hammer sizes, according to modelstandard on SUPER BMSoptional on BMShammer with 2 tungsten tipsstandard on BMS-Foptional on MINI BMS, BMS-L, BMS, and SUPER BMSThe information and images contained in the present documentation are to be considered reference values.SEPPI M. may carry out even substantail changes without previous notification.11

The Advantageof High QualityFounded in 1939 by Max Seppi and specializing in the manufacture of mowers since 1970, SEPPI M.is now one of the foremost manufacturers in its sector – not only in Italy, but throughout the world.“The best for farm and forest” – SEPPI’s motto commit the company to the manufacture of only thebest equipment whether for agriculture, forestry or greenspace maintenance.The decades of experience and tireless research for better technology and materials guaranteeproducts of the highest quality which will provide unrivalled service even in hard conditions.Discover the advantages offered by the equipment of SEPPI M.!a g r i c u l t u r a l, f o r e s t r y a n d i n d u s t r i a l m u l c h e r sSEPPI M. srl - Zona Artigianale 1 - 39052 Caldaro (Bolzano) ItalyTel. +39 0471 963550 - Fax +39 0471 962547 - sales@seppi.com - www.seppi.comSEPPI 09/2008AUTHORIZED DEALERIl nostro team è a Sua Ask disposizione our team for further information12