Package Crosscut Saws - Gp1.ro

Package Crosscut Saws - Gp1.ro

Package Crosscut Saws - Gp1.ro

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

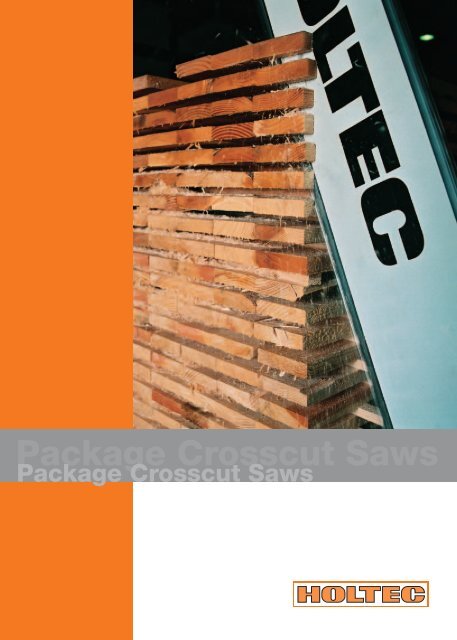

<strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong><br />

<strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong>

Demonstrate your quality thro<br />

The showcase of every sawmill is its timber yard.<br />

Today, post-cut product refinement is continuously gaining<br />

in importance. The grading and sorting of timber, proper<br />

package manipulation, drying and crosscutting to<br />

individual non-standard lengths are considered a must<br />

these days. For over 30 years now, today’s world market<br />

leader, HOLTEC, has offered reliable solutions for the<br />

package crosscutting of timber. From small, mobile<br />

machines to fully automated large-scale units, original<br />

HOLTEC package crosscut saws stand for precision and<br />

quality – over 6,000 times worldwide.<br />

HOLTEC systems are designed with durability in mind:<br />

robust, solid, and with low maintenance costs.<br />

For efficient crosscutting of lumber to individual lengths,<br />

the purchase of a package crosscut saw is the right<br />

choice. The processing costs per cubic meter of timber are<br />

clearly lower than the costs of hand-fed crosscut saws.<br />

Compared to individual crosscutting, the crosscutting of<br />

packages and partial packages also offers advantages<br />

after the cutting in regard to flexibility and storage.<br />

Final break-down and optimization of your packages can<br />

be determined right before dispatch. This will enable you<br />

to handle customer requests even on short notice and you<br />

will be ready to deliver quickly.<br />

<strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong> – Upgrade your Timber!<br />

Your Advantages:<br />

• Increased quality through better optical characteristics<br />

• Increase in value through additional processing<br />

• Flexibility through individual break-down of package<br />

after cutting<br />

• STIHL chains, the market leader’s quality products for<br />

optimal cutting results<br />

• STIHL chains, the market leader’s quality products for<br />

optimal cutting results.<br />

• Lower costs per cubic meter through efficient crosscutting system.<br />

• High value retention of machine through solid and robust construction.<br />

• Proven technology, thousand fold, worldwide.<br />

“HOLTEC crosscut“ – a quality label in the timber industry – and for good reason!

ough crosscut timber!<br />

CONTENT<br />

Entry Models<br />

Page 4 - 5<br />

Mobile machines,<br />

the easiest way for stationary<br />

crosscutting of packages<br />

Model Series ES 121<br />

Page 6 - 7<br />

The proven solution for package<br />

crosscutting<br />

Model Series Vario-Cut<br />

Page 8 - 9<br />

The high-performance solution for<br />

the pro.<br />

Special Systems<br />

Page 10 - 11<br />

<strong>Crosscut</strong>ting of gypsum, paper,<br />

cardboard, particleboard,<br />

MDF board and much more.<br />

Special Systems

4 <strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong> easycut<br />

Entry Models for<br />

Professional <strong>Crosscut</strong>ting<br />

Our entry models are highly suitable for crosscutting even a small amount of<br />

packages efficiently. With technology derived from the high-performance models,<br />

they are the right crosscut saws for the execution of clean cuts and first rough<br />

length cutting. These mobile package crosscut saws should not be missing at any<br />

timber yard – they are handy, precise, and allow for flexible usage. The Piccolo is our<br />

smallest mobile saw. It also serves as a base unit for our smallest stationary<br />

package crosscut saw, Piccolo-F/SHK. With these models, you can crosscut like<br />

the pros. Our model Kapp-Star is the star among the entry models. Robust and<br />

tested worldwide in the most extreme situations, it even cuts packages up to a cross<br />

sectional area of 1.3 x 1.3 m without any problem. Also available with gasoline<br />

engine – suitable for cutting logs, too.<br />

<strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong>

easycut<br />

<strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong><br />

5<br />

1 Piccolo F/SHK<br />

1<br />

Even the smallest stationary package<br />

crosscut saw performs like a true pro.<br />

Exact crosscutting for packages up to<br />

1.15 x 1.15 m and saw unit up to 6 m in<br />

length in the basic unit with manual swivel<br />

and drive, also available with electric swivel<br />

and system.<br />

2<br />

Our smallest - yet the greatest in cutting!<br />

Mobile package crosscut saw with easy<br />

design. Cutting equipment with 0.404 Stihl<br />

chain for extremely smooth surfaces and<br />

crosscuts with narrow kerf. For cross<br />

sectional areas of 1.15 x 1.15 m.<br />

3<br />

Robust all-in-one machine for trimmed<br />

timber and round timber.<br />

Standard guide bar with 190 cm cutting<br />

lenght for cross sectional areas of up to<br />

1.3 x 1.3 m. An 11 KW electric drive engine<br />

output provides high chipping performance.<br />

Available with electric motor or gasoline<br />

engine.<br />

2 Piccolo 3 Kappstar

6 <strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong> ES121<br />

Our Success Model ES 121<br />

More than 1,500 machines delivered worldwide in over 30 countries – the successful<br />

results of a success story for more than 30 years. High cutting accuracy and solid<br />

construction distinguish this machine. An ideal distribution of the cutting force<br />

generated by the swivel motion ensures clean cuts – package by package.<br />

Through the individual choice of the cutting equipment, packages of up to<br />

1.75 x 1.75 m can be crosscut in the desired quality. Available with mobile package<br />

carriage, positioning saw unit with marginal space requirement, or in combination<br />

with rollerways. Customized for your needs and requirements.<br />

<strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong>

ES121<br />

<strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong><br />

7<br />

1<br />

ES 121 SHK<br />

1<br />

ES 121 SHK with package carriage and<br />

stationary saw unit.<br />

By means of the mobile carriage, the<br />

packages are positioned accurately under<br />

the saw. An asset of device allows for the<br />

opening of the kerf after crosscutting and<br />

the simultaneous execution of feeding,<br />

crosscutting and unloading.<br />

2<br />

Model ES 121, a model with positioning<br />

crosscut unit.<br />

Ideal for precise trimming (first and final cut)<br />

of packages and for all customers with<br />

limited space.<br />

3<br />

Saw unit combined with rollerways before<br />

and after the saw.<br />

Ideal for the automatic processes of<br />

product lines. Strapping devices, which<br />

can also be used to tie up squared timber,<br />

can be integrated.<br />

2 ES 121 F/SHK<br />

3 ES 121 RAK

8 <strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong> variocut<br />

Our Versatile High-Performance Model<br />

Our model VarioCut is tailored to the needs of our high-performance customers in<br />

particular. This machine and its concept are distinguished by a robust saw basic unit,<br />

a very sturdy, vertical bar guidance, and the option of variable control of the guide<br />

bar during the crosscut. The reinforced drive with 17 KW output provides short cycle<br />

times within the crosscutting process as well as high throughput. The VarioCut<br />

Series can also be perfectly integrated into automated systems. Like the basic<br />

model, ES 121, this model is also available with mobile package carriage<br />

(SHK Series), positioning saw unit (F/SHK), and in combination with rollerways<br />

before and after the crosscut saw (RAK).<br />

<strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong>

variocut<br />

<strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong><br />

9<br />

1<br />

Vario-Cut SHK<br />

1<br />

<strong>Package</strong> crosscut saw with mobile package<br />

carriage and stationary saw unit.<br />

The guide bar is guided through the package<br />

at an angle of 0 - 15°. The positioning of<br />

the packages is carried out through an<br />

electronically controlled carriage. The kerf<br />

can be opened by use of the unloading<br />

device - a requirement for optimal crosscutting<br />

of multiple lengths (photo shows<br />

system with two set-off devices).<br />

2<br />

Design featuring mobile saw unit and stationary<br />

package support block.<br />

Ideal for trimming (first and final cut) of<br />

packages. Through self-supporting rail guide,<br />

any system length is possible. Can also be<br />

used for the crosscutting of derived timber<br />

products in any length.<br />

3<br />

Saw unit in combination with rollerways<br />

before and after the saw unit.<br />

By request, with integrated alignment units.<br />

Can be combined with strapping devices and<br />

can also be used to tie up squared timber.<br />

2 Vario-Cut F/SHK<br />

3 Vario-Cut RAK

10 <strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong> Special Systems<br />

Machine Surroundings<br />

Who likes to cut timber efficiently needs an ideal system surrounding. Here HOLTEC falls back to long lasting experiences<br />

form the plant construction. Well-integrated waste conveyor systems, aligning systems and strapping<br />

devices are certainly compatible.<br />

We supply complete systems from one source - for your benefit!<br />

Our experiences in cutting timber are the base for the design of crosscut<br />

saws also in other industries. The successful use in the gypsum-, paper- and<br />

derived timber industry supports that HOLTEC systems cut more than timber.<br />

In doing so these special materials ask for special extra devices such as:<br />

• special saw chains<br />

• variable cutting lengths up to 2.5 m<br />

• exhausting systems<br />

• dust protection devices<br />

• saw units with vertical chain guiding<br />

• product compatible transport systems as rollerway,<br />

tapered rollerway,chain conveyor, etc.<br />

Please contact us - we are looking forward to advise you<br />

in special applications of every description.<br />

Performance specifications and drawings are to be regarded as symbols and guiding values only. Subject to change without notice.<br />

<strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong>

Special Systems<br />

<strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong><br />

11<br />

Special Systems<br />

Control cabins and<br />

system enclosure<br />

Systems for package alignment<br />

Waste evacuation systems<br />

Veneer<br />

Fleecerollen<br />

Special System Verti-Cut<br />

Systems for cutting Gypsum plaster board<br />

Gypsum plaster board<br />

Derived timber products<br />

(chip, MDF, OSB)

Our agencies worldwide<br />

HOLTEC GmbH & Co. KG<br />

Anlagenbau zur Holzbearbeitung<br />

Dommersbach 52<br />

53940 Hellenthal<br />

phone: +49 - 2482 / 82 - 0<br />

fax: +49 - 2482 / 82 - 25<br />

info@holtec.de<br />

http://www.holtec.de<br />

HOLTEC USA Corporation<br />

P.O.Box 2190<br />

FL-33509 Brandon<br />

USA<br />

phone: +1 - 813 / 7541665<br />

fax: +1 - 813 / 7528042<br />

holtec@worldnet.att.net<br />

http://www.holtecusa.com<br />

BZH<br />

Baljer & Zembrod, HOLTEC S.A.R.L.<br />

Chemin de la Briquerie<br />

Marolles - B.P. 223<br />

F-51361 Vitry-le-Francois<br />

FRANCE<br />

phone: +33 - 326746361<br />

fax: +33 - 326740716<br />

contact@bzh-sarl.com<br />

BZÖ<br />

Baljer & Zembrod GmbH<br />

Aderstrasse 44<br />

A-4850 Timelkam<br />

AUSTRIA<br />

phone: +43 - 7672 / 95475<br />

fax: +43 - 7672 / 95254<br />

office@baljer-zembrod.at<br />

SAGSPECIALISTEN AB<br />

Datorgatan 4<br />

S-561 33 Huskvarna<br />

SWEDEN<br />

phone: +46 - 36 / 139890<br />

fax: +46 - 36 / 138888<br />

info@sagspecialisten.se<br />

http://www.sagspecialisten.se<br />

HOLTEC TIMBER TECHNOLOGY<br />

P.O.Box 159<br />

West Park Village<br />

NZ-Auckland 1008<br />

NEW ZEALAND<br />

phone: +64 - 98334577<br />

fax: +64 - 98323477<br />

holtec@paradise.net.nz<br />

http://www.holtec.co.nz<br />

FALKENBERG EFTF.<br />

AS Maskinforretning<br />

Billingstadsletta 30<br />

Postboks 263<br />

NO-1361 Billingstad<br />

NORWAY<br />

phone: +47 - 66778900<br />

fax: +47 - 66778901<br />

info@falkenberg.no<br />

http://www.falkenberg.no<br />

HOLTE OY<br />

Toukolantie 13<br />

FIN-15880 Hollola 3<br />

FINLAND<br />

phone: +358 - 3 / 7801746<br />

fax: +358 - 3 / 7801745<br />

holte@kolumbus.fi<br />

SIA OBERTS<br />

Gaujas iela 32/2<br />

Rigas raj.<br />

LV-2167 Marupe<br />

LATIVA<br />

phone: +371 - 7810666<br />

fax: +371 - 7810655 vilmars@oberts.lv<br />

http://www.oberts.lv<br />

PFZ<br />

Jacek Kubiak<br />

Przedstawicielstwo w Polsce<br />

PL-91-604 Lodz, ul. Opolska 33<br />

POLAND<br />

phone1: +48 (42) 6508637<br />

phone2: +48 (42) 6339932<br />

Mobil: +48 (601) 299933<br />

jacekk@pdi.net<br />

http://www.holtec.republika.pl<br />

Scanlesthekh<br />

Pervomaiskiy Pr. 50<br />

RUS-185001 Petrozavodska<br />

RUSSIA<br />

phone: +7 - 8142 / 771105<br />

fax: +7 - 8142 / 771105 olkhina@olkha.ru<br />

http://www.olkha.ru<br />

NEW CENTURY SAWMILL<br />

SOLUTIONS<br />

P.O. Box 283 Cresta<br />

ZA-2118 JOHANNESBURG<br />

SOUTH AFRICA<br />

phone: +27 - 114780900<br />

fax: +27 - 114783759<br />

newsaw@global.co.za<br />

HOLMAG<br />

Holzbearbeitungsmaschinen AG<br />

Mauer<br />

CH-3454 Sumiswald<br />

SWITZERLAND<br />

phone: +41 - 34 / 4312 72 3<br />

fax: +41 - 34 / 431126 2<br />

info@holmag.ch<br />

http://www.holmag.ch<br />

WOODTECH-MACHINERY<br />

Unit 7<br />

New Mills Ind. Estate<br />

Inkpen Nr. Hungerford<br />

Berkshire RG 17 9 PU<br />

GREAT BRITAIN<br />

phone: +44 - 1488 / 66 87 07<br />

fax: +44 - 14 88 / 66 82 03<br />

sales@woodtech.co.uk<br />

http://www.woodtech.co.uk<br />

Our business divisions:<br />

Logyard Mechanising<br />

<strong>Package</strong> <strong>Crosscut</strong> <strong>Saws</strong><br />

Complete logyards<br />

Service